Casting post-treatment is the last process in aluminum casting production, which exerts important influence on the quality. But different post treatment has different corresponding effect. For example, heat treatment is used to improve or change the original structure of aluminum casting to eliminate the internal stress, ensure casting performance and prevent casting deformation and damage.

The heat treatment of aluminum casting aims at different working conditions, generally including quenching, annealing, normalizing, as-cast quenching and tempering, artificial aging, stress relieving, softening and graphitization, etc. For example, casting requires high wear resistance and sufficient toughness whose internal structure should be austenite. For this reason, it is necessary to quench the casting that can be heated to the austenite region to make it completely austenitic, and then quenched and chilled quickly so that the austenite has no time to change and keep down.

The post-treatment of aluminum casting is divided into three aspects: correction, repair and surface finishing.

1. Correction

Because some castings will be deformed in different degrees during solidification, cooling and heat treatment, making some dimensions are out of tolerance. It is necessary to repair them by means of correction. Correction is mainly carried out at normal temperature or warm state by mechanical force. When the deformation is too large, high temperature correction can also be carried out in the heating furnace by casting dead weight or external pressure weight.

2. Repair

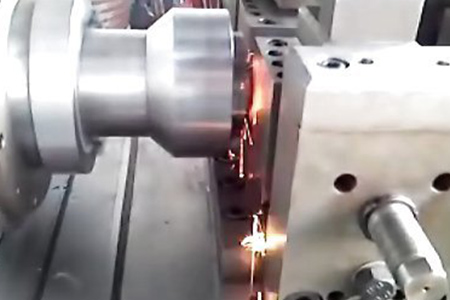

The external defects of aluminum castings are mainly repaired by welding.

3. Surface finish

Casting surface roughness and unevenness are generally polished by suspension and high-speed grinding wheels.