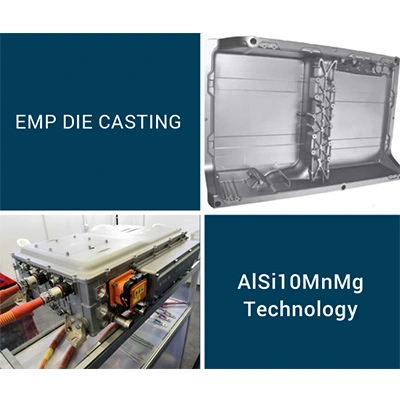

In the dynamic landscape of industrial manufacturing, OEM aluminum die casting stands as a cornerstone technology, enabling the production of lightweight, durable, and complex components. EMP Casting specializes in delivering tailored die-casting solutions that align with international standards, empowering industries from automotive to renewable energy to achieve both performance and cost efficiency.

Aluminum die casting combines high strength-to-weight ratios, excellent thermal conductivity, and corrosion resistance, making it ideal for applications demanding precision and longevity. Compared with traditional steel parts, aluminum parts can reduce weight by up to 60%, helping electric vehicles to achieve lightweight design and extend driving range. The process also supports complex designs with a tolerance control of ±0.02 mm, reducing the need for post-processing and shortening delivery cycles.

End-to-End Solutions: From mold design to surface finishing (anodizing, powder coating, etc.), we ensure seamless production under ISO 9001 and automotive certifications like IATF 16949.

Material Versatility: We work with ADC12, A380, A356, and other alloys to meet diverse mechanical and environmental requirements.

Precision & Scale: Equipped with vacuum die casting and CNC machining, we produce components ranging from 0.1kg to 10T, supporting both prototypes and mass production.

Automotive: Engine blocks, transmission housings, and structural parts that enhance fuel efficiency and durability.

Renewable Energy: Solar panel brackets and wind turbine components resistant to harsh environments.

Aerospace & Electronics: Lightweight housings with EMI/RFI shielding capabilities.